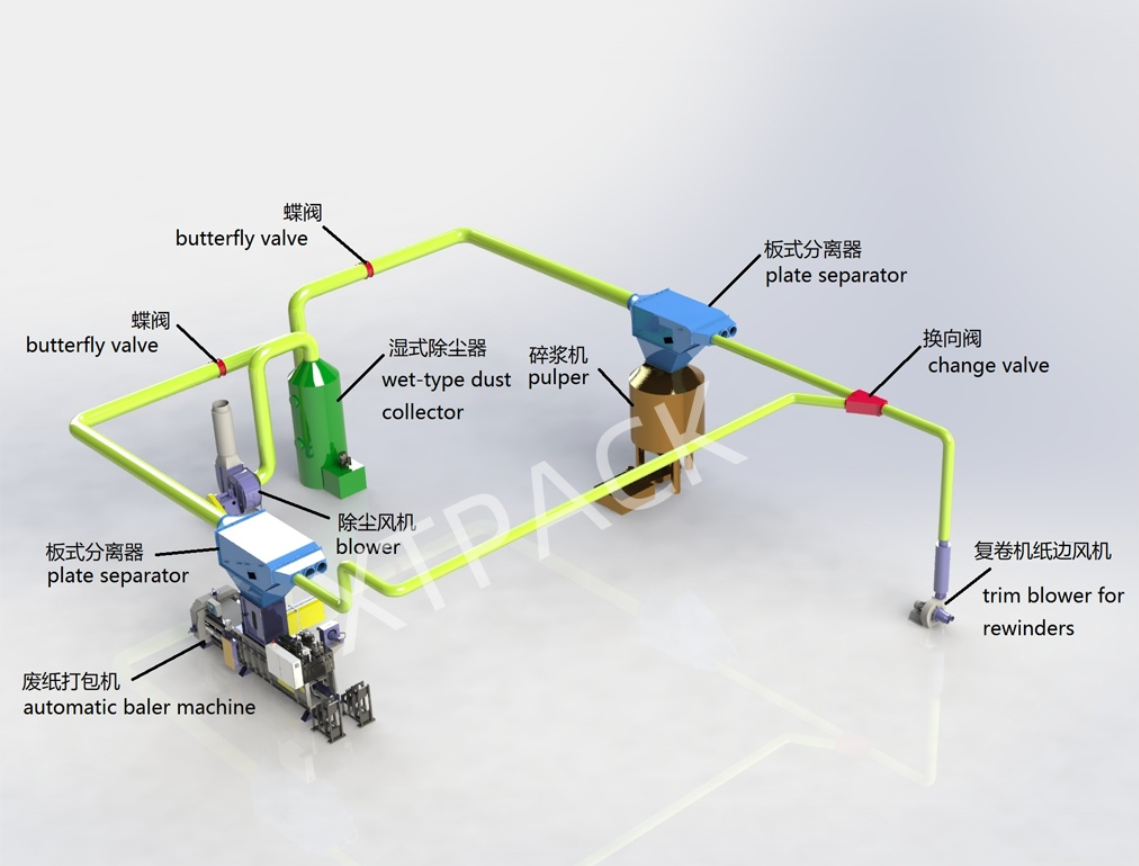

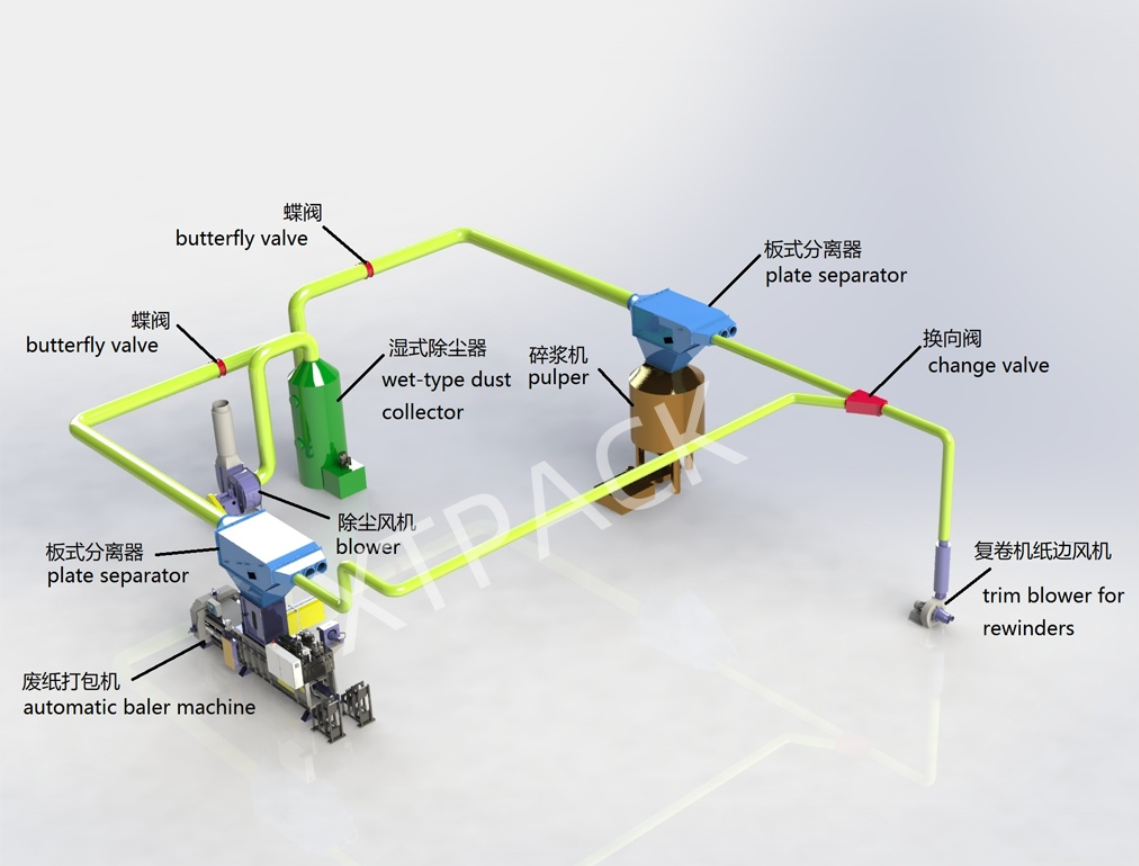

Paper Mill Pulper Waste Baling System

The whole process of paper mill pulper waste baling system:

1. Paper trims of the rewinder are sucked into the blower through the negative pressure suction pipes. The blower shreds these paper trims. After shredding, the paper trims will enter the conveying pipe through the outlet of the blower with positive pressure and goes straight into the plate separator in the packaging room.

2. The waste falls into the baler for packing.

3. The dusty air passes through the plate separator and then enters the wet-type dust collector. After the air is filtered and dehydrated, the clean air will be discharged to the outside through the dust removal fan.

4. Through the pneumatic changing valve, the waste conveying pipe can be switched to the plate separator above the pulper according to the actual situation (at the same time, the dust removal pipe can be switched through the butterfly valve), and the damaged paper is sent to the pulper for regeneration.