In today's world, sustainability and environmental consciousness have become increasingly important. As a result, industries across the globe are recognizing the need to adopt eco-friendly practices, especially when it comes to waste management. One such area where significant progress has been made is PET bottle recycling. This blog will focus on the importance of employing semi-automatic horizontal baler machines for efficient PET bottle recycling, with a particular emphasis on the renowned brand, XT Pack Baler.

Understanding the Need for PET Bottle Recycling

The accumulation of plastic waste, particularly PET bottles, has become a pressing issue for our environment. These bottles take years and even decades to decompose, polluting our oceans, landfills, and affecting the overall ecosystem. Efforts to recycle PET bottles have proven to be an effective solution, significantly reducing environmental impact while preserving valuable resources.

The Role of Semi-Automatic Horizontal Baler Machines

Semi-automatic horizontal baler machines have become an indispensable part of PET bottle recycling facilities. These machines are designed to compress and bundle large quantities of PET bottles quickly and efficiently, making them easier to handle in further steps of the recycling process. The automated functionality of these baler machines streamlines the overall recycling operation, enhancing productivity and reducing labor costs.

XT Pack Baler's Superiority in PET Bottle Recycling

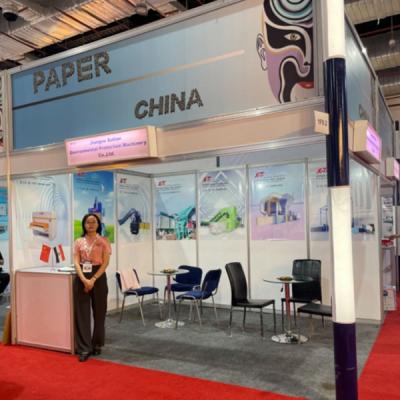

Among the leading brands in the market, XT Pack Baler stands out as a reliable and renowned manufacturer of semi-automatic horizontal baler machines. With their innovative technology and commitment to sustainability, XT Pack Baler machines offer numerous advantages to PET bottle recycling facilities. Robust construction, user-friendly interfaces, and precise compression capabilities are some of the key features that make these machines stand above the competition.

Benefits of Investing in XT Pack Baler's Semi-Automatic Horizontal Baler Machines

Enhanced Efficiency

XT Pack Baler machines are designed to handle a substantial volume of PET bottles, significantly increasing the productivity of recycling facilities. With their semi-automatic functionality, these machines minimize manual labor, reducing operational costs and improving overall efficiency.

Space Optimization

The compact design of XT Pack Baler machines enables effective space utilization within recycling facilities. As these machines can be integrated into existing workflows, they eliminate the need for additional storage space, ensuring a streamlined recycling process.

Customization Options

XT Pack Baler offers a range of semi-automatic horizontal baler machines, allowing recycling facilities to choose a model based on their specific requirements. This flexibility ensures maximum output and efficiency in PET bottle recycling operations.

Cost Saving

Adopting XT Pack Baler's semi-automatic horizontal baler machines can lead to substantial cost savings in the long run. Reduced labor costs, increased processing capabilities, and improved overall efficiency contribute to a more economically viable and sustainable recycling process.

As the demand for PET bottle recycling continues to rise, investing in reliable and efficient equipment such as XT Pack Baler's semi-automatic horizontal baler machines is crucial. These machines not only streamline the recycling process but also contribute to the preservation of our environment. By choosing XT Pack Baler, recycling facilities can achieve optimal productivity and efficiency, taking a step towards a greener future.